Cerámica de la Cartuja - La Cartuja's ceramics

Andalusian fine pottery worked in the Monastery of La Cartuja of Seville in the nineteenth century. Nowadays it is manufactured in Salteras.

A total staff of 12 ceramists create printed earthenware, white slabs of flint, earthenware decorated with calco varnish, painted and opaque porcelain.

Technique: a solid mixture is spread over the mould and dried. A liquid mixture is prepared and injected into plaster moulds for the first cooking, at 1.120 degrees for 12 hours. Then pieces are bathed in a liquid pore cap before being decorated. Colour is fixed with a second baked between 700 and 850 degrees for 20 hours, being immersed afterwards in white glaze. It is baked for the last time at 1.015 degrees for 12 hours. Burrs are removed and small imperfections are polished.

Main materials: clay from England, kaolin from Burela, sand from Cadiz, calcium carbonate, silica and feldspar.

Cristal glass manufacturing

Demonstration of TOURROULAGE

The video

shows the technique of “tourroulage”

used by Belgian artisans in order to create items with pottery, such as vases

of different shapes and size. The technique consists in using few instruments,

shaping the pottery only with hands and fingers.

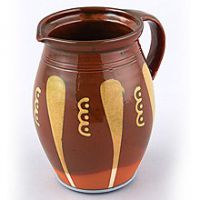

Folk pottery from Chalupki

Chalupki is a small village located in the Swietokrzyskie region. The village is famous not only in Poland but also across Europe for its traditional of pottery. The beginnings of pottery in Chalupki dates back to the sixteenth century. In the year 1.935 there were as many as 69 pottery workshops, but 40 years later - only 40 workshops. The skills and pottery tradition are handed down from generation to generation. Usually whole families were engaged in this extremely rare craft.

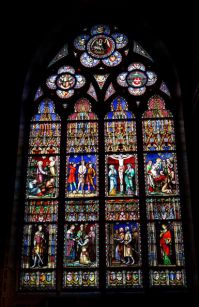

Glass painting

The pictures painted on the glass belonged to a typical manifestation of folk painting. Originally they portrayed religious and secular themes. Pictures of saints were thought to protect their owners. The secular images with the Jánošík's highwaymen group are original Slovak contribution to the European paintings on glass. The families who earned their living through making glass originally started to produce these paintings.

Thin glass is used for glass painting. The painter puts the graphic artwork under the glass and draws the contours of the main design, the more experienced painters paint without the graphic original. The contour lines are painted with thin brush and sparse black colour. After the contours dry, the details are painted, e.g. faces, then larger areas, and finally the background. Originally, the water-based tempera colors were used for the glass painting. To adhere better to the glass surface, the color was mixed with egg yolk or other ingredients. The current authors use special colors for glass or oil paint, which dry longer, but are more durable and beautiful. The self-made brushes made from the animal hair were originally used for the glass paint. Currently the purchased brushes are used.

Horezu traditional ceramic vessel

Horezu ceramics is a unique type of Romanian pottery that is traditionally produced around the town of Horezu in northern Oltenia (Vâlcea County). The craftsmanship of Horezu pottery was inscribed on UNESCO Intangible Cultural Heritage Lists in December 2012. The techniques used to create the beautiful Horezu ceramics are coming from ancient times, more than 2000 years. The first video presents a potter and his family who shape, decorates and then burn a vassel.The process begins by bringing the reddish clay in the potter's workshop, where it is processed. The obtained paste is cleaned of impurities, is divided into balls and then worked on the wheel.Creating a pot requires a special technique and a high working speed because the paste should not dry.After modeling, the pots are left to dry for a few days in the shade and then burned in special ovens after they have been previously ornamented and eventually blushed.The dominant symbol of Horezu painted pots is the rooster along with we can meet other traditional symbols.The colours are vivid shades of dark brown, red, green, blue and ‘Horezu ivory’.

La Rambla ceramics

La Rambla pottery is a ceramic characteristic for its whiteness, and its porous clay with astonishing ability to cool the liquid content of botijos, bowls, jars, bottles, etc. It is also used Ffor making accessories for kitchenware, gardening and constructions, such as tiles and lighting elements.

Technique: the clay is obtained from the soil, cleaned of impurities and spread under the sun. Next, it is sieved and kneaded, and then molded by the lathe creating the desired shapes. Then it is dried and baked in the oven at 1000º C. Finally, it is glazed with colored glass, decorated and polished, and finished with a second cooking.

Main material is local ground pot, clay, water and salt.

First findings of bell-shaped glasses locally made in La Rambla (Cordoba) date from the Bronze Age. This prehistoric pottery got its consolidation during the period of Arab occupation. The most emblematic of the history of pottery from Rambla date is 1460, when first written reference.

Lapithos water jars

-The art of glazed pottery, which comes from Byzantium, appeared in Paphos and Lapithos in the 14th century AD.

The raw material for pottery was - and continues to this day to be - clay, which in the case of Lapithos pottery must be of very good quality, free of foreign matter, sticky and fine. This type of clay, which can only be found in Lapithos, was named kouliastos, from the way it is processed.

In the early 20th century, during World War I and the period after that, the descent of the Asia Minor craftsmen proved an important landmark in the history of Lapithos pottery making.

The art of pottery is deeply rooted in Lapithos and inseparably linked to the inhabitants. Some craftsmen would add the capacity “Potter” after their signature on their creations, as it was considered a special honour.

Manufacturing of "Teste di Moro" in Caltagirone's pottery

The video shows the different stages of production of the famous and precious "Teste di Moro", a typical piece of Sicilian handcraft. The process consists in different steps: the first step consists in giving shape to the creation and this happens through two important steps: turning and modelling. The second step is the drying: each piece after taking shape is left to expel all the water contained in the clay and when it is completely dry it will pass to the first firing in the oven for about 13 hours. After the first firing, all the pieces are painted and retouched by taking a white colour. Once the painting is finished, the pieces are ready to pass into the hands of the decorators, who will give colour and style to the creation. The last step is the second firing in the oven and it is the most important phase where everything acquires brightness, thus enhancing colours and shapes.

Manufacturing of Gille Masks

The Binche Carnival is the most famous carnival event in Belgium. There is evidence of Binche Carnival since 1395, when people used to meet around a bonfire the day of Marti Gras to celebrate the winter’s end, but the Carnival as we know it today goes back to 1500. The traditional character is the “Gille”, a peasant mask, worn by everyone in Marti Gras and that costume is totally handmade. In the video there is an example of the manufacturing of Gille masks. The artisan explains that he uses the basic mold in order to give the mask the right form. Then, he paints on the masks the typical moustache and the glasses.

Marginea black pot

Marginea black pottery is unique in Europe. Its emblem being the black colour ceramic that is obtained without the use of paints.

Tradition of pottery is old at Marginea (Bucovina, Suceava County), descending to 1500. Some authors appreciate that the black ceramics at Marginea is a Dacian heritage, given the presence of this type of pottery in some Geto-Dacian and Neolithic archaeological sites.

The handcraft of black ceramics has been passed along generations, and now there are only few potters in Marginea.

The "secret" of black ceramics lies in the way of burning. Thus, towards the end of the burning, all the openings of the furnace are closed, and the burning continues to be stifled, the smoke impregnating the surface of the vessels. Grinding with a quartz-rich stone gives a great metallic gloss.

The decoration technique is a traditional one: the pots are polished with a special stone, the traces of the gray on the walls of the pot is mixed with their metallic black.

To this technique is added the use of geometrical motifs and ornaments: spirals, broken lines, fir branches.

Master ceramist

Murano Fornace Colleoni, Manufacturing of glass

Passion for the pottery

Polish Pottery from Boleslawiec

Pottery is a top brand of Boleslawiec, a Polish city in the Lower Silesia for a very long time. Produced from the beginning of the nineteenth century until today, it has not changed its original and unique character. Its unique appearance has survived to these days in its original form. Each piece of the ware is hand-painted or stamped. In this way, each product is original and unique. All ceramic vessels and other products are made from stoneware. They are formed, then hand-painted and burned at temperatures over 1.250 degrees Celsius.

Pottery from Paphos

Pottery in Cyprus dates back to the Neolithic period. Archaeological findings confirm that people were using pottery from clay in their everyday life at that time and even decorated their homes with them. The artists of that time already knew how to make a glaze and had developed polishing techniques. Ceramics were often decorated with a range of paintings and ceramic masks were used in the rituals of religious ceremonies. It is thought that most impressive forms and decorative patterns were invented as early as the Early and Middle Neolithic period. The same period gave us numerous early terracotta statuettes, mostly of the female form. Clay figurines were important in holy sanctuaries as well as households

Pottery of Slovakia

The mug is produced by classical technology from the clay on the potter's wheel in this video. The ceramics was produced with this technique in the whole Slovakia. Individual regions differed by their decorations. The western Slovakia is known by majolica pottery from the Modra region and the eastern Slovakia by the pottery from Pozdisovce region.

The head is first prepared as the foundation – a piece of clay is cut out to make the matter better adhering. The bottom of the mug will expand. From the bottom of the mug the tile begins to pull up. When the tile is pulled out, it can be shaped (before it is still possible to cut the bottom). The abdomen is pressed. The inside is sucked off with a water sponge, so that the mass will not be dissolved later. The creature gets its final shape with a blade and then is smoothed with a sponge. Finally the pouring hole is formed and the ear is attached. After drying, the mug is fired in an electric kiln at the temperature of 950 degrees Celsius. After the first firing, the mug is glazed. Consequently it goes for the next firing, in which the glaze spreads to form a thiny glassy layer.

Stained-glass technique

The glass blowing art

The art of glass blowing was first discovered in the Middle East along the Phoenician coast in 20 B.C. This new technique changed the use of glass from jewelry and ornaments to necessities.

Glass blowing of vases and art objects is still done in basically the same way as it was originally done. Glass blowers dip in a iron pipe in the melt and roll a small amount of molten glass on the end. Then they roll the molten glass against a paddle or metal plate to give it an initial shape. Blowing into the pipe they create a bubble and with wooden paddles with holes and wet newspapers they shape the glass. Shears can be used to cut the softened glass. Additional melted glass can be applied and shaped into stems, handles, and other decorative artwork. The hot piece of glassware can be dipped into molten glass of a contrasting color. Glass of all types can be colored by the addition of metals, metal oxides or other compounds to the melt.

The Lemko Glass Bead Collars - Krywulki

Tradition and innovation united in ceramics moulded by the Mediterranean

Traditional Pottery of Cyprus

Pottery in Cyprus dates back to the Neolithic period. Archaeological findings confirm that people were using pottery from clay in their everyday life at that time and even decorated their homes with them. The artists of that time already knew how to make a glaze and had developed polishing techniques. Ceramics were often decorated with a range of paintings and ceramic masks were used in the rituals of religious ceremonies. It is thought that most impressive forms and decorative patterns were invented as early as the Early and Middle Neolithic period. The same period gave us numerous early terracotta statuettes, mostly of the female form. Clay figurines were important in holy sanctuaries as well as households

Unique pieces to reclaim the artistic status of pottery

Soon he got interested by the secrets of ceramics and learnt how to use the potter’s wheel in the workshop of the Góngora brothers.

In 2000 he filmed a documentary about pottery in Níjar, which shows every step of the manufacturing process, so this legacy didn’t disappear. He applies his xylography and drawing skills to his works, something that makes them unique.