Alabaster carving

Alabaster is a singular variety of gypsum, finely crystallized, with light colors, which appears in compact and homogeneous masses called nodules. There are alabaster mines in different parts of Europe and this craft has usually been developed around it.

Alabaster must be extracted from the mine, transported and cut according to the type of use to which it is destined. Without separating it from the world of art, which in other times was directly linked, today, alabaster has many applications, both in architecture, as in lighting and ornamentation.

The technique of sculpting consists of extracting, by means of a hammer and chisel, punch or chisel, the excess material to give shape to the figure that has previously been drawn. Drilling, sawing, polishing machines, etc., can also be used.

Artist sculpts 80-pound art piece from a 1200 pounds marble

An

example of a sculpture created by an artist using a marble piece from Carrara. He delicately and patiently cuts,

shapes and polishes the marble until he obtains the sculpture.

Creative flowerpots

This instructive film shows how to make by hand stylish flower-pots from cements according to old design. Simple way to make by hand flowerpots at home.

Gypsum casts

The Royal Foundry in the Royal Lazienki Museum in Warsaw provides an Instructional video that shows how to prepare a cast of traditional gypsum ornaments from ready-made forms. The Royal Foundry has been operating since the 18th Century teaching crafts, in which plaster copies of ancient and modern sculptures were made. Gypsum castings were popular in eighteenth-century collections of European monarchs. Currently, the studio is conducting workshops for students of various schools during which students learn about the famous antique sculptures and related myths. The instructional film shows the casting of a floral motif.

Imagination sculpted from stone

Juan Moral, a sculptor who creates spaces full of warmth and life

Macael marble mortar and pestle

The marble mortar from Macael is an artisanal piece that works as a kitchen utensil, to grind, chop, crush, prepare sauces, etc.

The mortar artisans use to sculpt each piece by hand, with pointer and chisel.

Technique: extraction of white Macael marble from open-cast quarries, selection of the most suitable type, cut the pieces in blocks of different sizes appropriate to the size of mortar. Portions are passed through the vertical milling machine to be emptied, as well as the interior grinding to leave inside and outside a suitable finish for the use to which the mortar will be destined. The “mochetas” (notches) are made and the whole piece is finished with a sanding process

It is made of 100% white marble from Macael, has a medium granulometry and mineralogical composition of 83% calcite, 16% dolomite, 1% muscovite, and minor amounts of clay and opaque.

The well-known marble of Macael is extracted from the quarries of the Almerian town of Macael since the Ancient Age. This marble is highly appreciated and recognized for its purity and beauty.

Plaster sculpture technique - Ecce Homo sculpture

Sharpening with Belgian Blue Stone

The video shows the act of sharpening with a Belgian blue stone, considered one the best tools to sharpen knives.

Stone marble sculpture, Stone carving - The kiss of death sculpture

Stone statues

In the video we can see how one of the few stone craftsman that still exist, Ion Moaca, from Pietroasele, Buzau County, skillfully manages the chisel and the hammer to create unique stone statues. The stone master has a real outdoor statues museum, which calls it "The Stone Age." He carved the stone giving it all sorts of shapes, like animals, birds, people, and every statue has a story that only the stone master saw it in the stone block.

The craftman considers stone carving as a gift received from the God and his predecessors. He likes to work using traditional tools such as chisel and a hammer, just like his predecessors.

The craft was inherited from his father and it will go out with him because he has no apprentices to follow his footsteps.

Stonemasonry

The Art of Mosaic

The video

shows one of the most important school of mosaic artisans in the world. The

first step in order to create a mosaic is to draw the pattern that the mosaic

should have. Then, the mosaic artist need to choose the right material and

stones. By breaking the different pieces of stones, the artisans obtain these

small tiles that will compose the mosaic. The tiles are then covered with

different colours and put together in order to create the pattern.

The Polishing and Shining Marble Black Belgium design by Emanuele Rubini sculptor

The video

shows the work of the sculptor Emanuele Rubini. His work consists in breaking a

big piece of black marble with the hammer in order to obtain the perfect block

of marble he needs for the sculpture. Then, he works and shapes the marble with

specific instrument. The final step of the work consists in polishing and shining

the marble.

The sand stone fountain

In this video a sand stone fountain is made by Pavel Surma. He is an artist who has been intensively involved in creation of art which includes painting, sculptures, graphics, photography and collages. After a longer stay abroad, since 2001 he has lived and worked in the Czech Republic, specifically in Ludmirov in the Prostejov district. In the recent years, he has devoted himself to the interior and exterior design, where he integrates especially sand stone sculptures.

The fountain consists of the base, the central motif – sculpture in its center and the rim around the fountain. The larger part of the fountain is prepared in the workshop or atelier. Finally, the fountain is set up on the land and filled up with water.

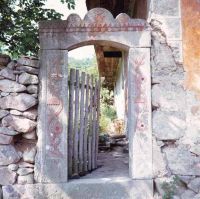

Vistea stone - traditional carving techniques

The video presents how the stone of Vistea is processed using modern techniques (with mechanical cutter and a grinder) but also traditional methods of carving the stone with chisel and hammer, methods transmitted cross generations.

In the workshop the work is done manually, except cutting limestone wich is done with a mechanical cutter and the grinder.

After the stone blocks are extracted from the quarry they are working on lathe and the final plates are carved manually, using the chisel and the hammer, to give value and to enrich the stone. The results are hand-crafted finished products such as: statues, massive columns, chapters but also industrial products: stairs, windows, horizontal and vertical plywood, interior decorations, sidewalks.

The craftsmen and the limestone of Vistea have a centuries-old history in the stone carving, the craft being passed from generation to generation, 80% of the working population from Vistea village works with stone.

The Vistea limestone has several advantages that have made it famous: the pleasant color (white, yellow or blue, depends on which career is extracted), it is durable and has good mechanical properties. In addition, it is abundant in the hills near Cluj.

The name of the village Vistea has been linked, over the years, to the natural stone that made it famous in Central and South-Eastern Europe, the village being certified in the 13th century.